About Us

About Us

- Unparalleled, Choice CNC Grinding Solutions

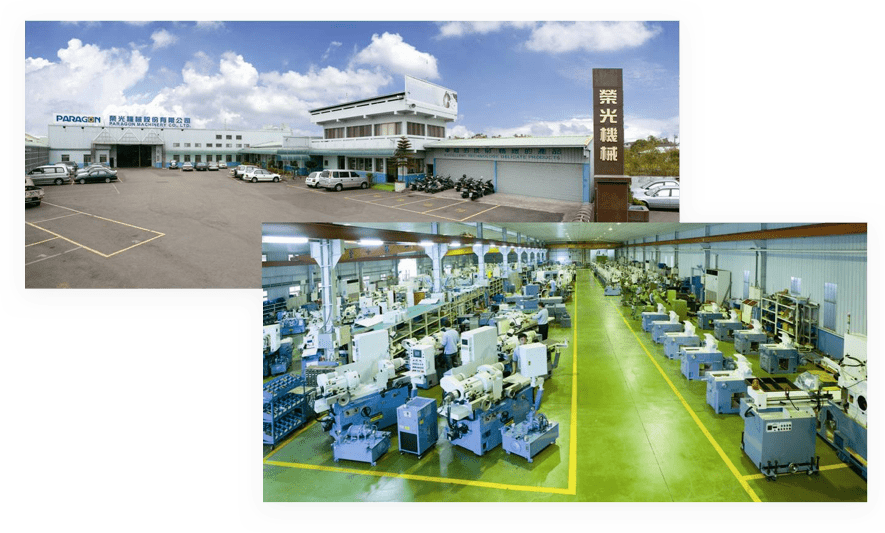

Founded in 1968 and headquartered in Taichung City, Taiwan, PARAGON MACHINERY is dedicated to designing multi-function, high precision grinding machines for metalworking parts. PARAGON started from traditional small centerless grinding machine and has now evolved into a complete CNC grinding product line including centerless grinders, internal grinders, universal cylindrical grinders and ID/OD Twin-Spindle grinders. Our products can be founded in various industries such as aerospace, automotive, medical and electronic equipment.

PARAGON distributes machines in 40+ countries across the world. Our business concept is “competitiveness, quality assurance and customer satisfaction” making PARAGON keep working as a trustworthy brand for customers.